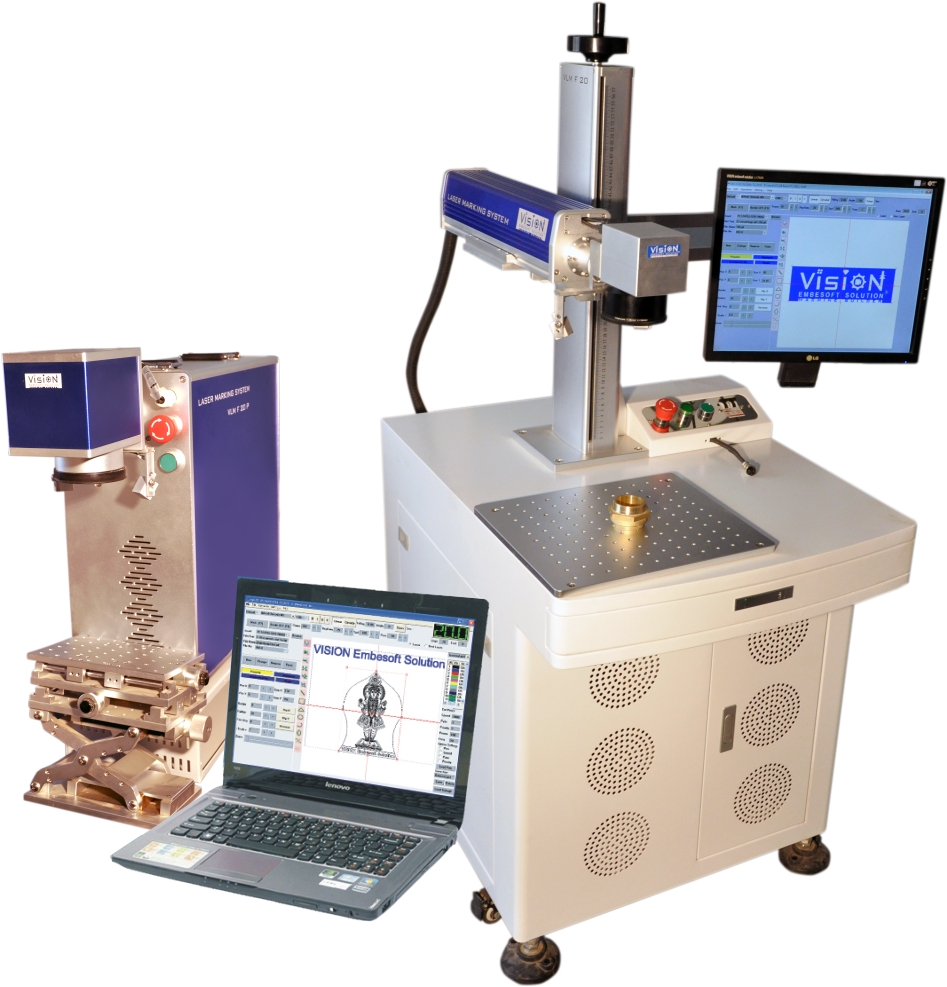

The use of laser marking systems is a permanent and versatile way to identify parts. Diverse industries use high-speed, low-impact laser machines for a variety of purposes.

Due to the low maintenance, minimal energy consumption, and ease of operation, Laser engraving on metals has become a popular option for part marking. A laser’s MTBF (mean time between failures) ranges from 30,000 to 100,000 hours, making it both efficient and reliable. Laser marking equipment also has a small footprint and is easy to integrate.

Due to the fact that there is no “one-size-fits-all” solution for laser marking, we offer a wide selection of machines. RMI Laser has been designing and manufacturing laser marking systems since 1998. Our top priority is to make sure you receive the best laser for your specific requirements. Using our in-house experts, we ensure you receive a laser that is right for your needs. We set ourselves apart from the competition by offering personalized solutions.

Lasers are capable of producing many types of markings, including engraving, annealing, etching, foaming, etc. Marking on a wide variety of substrates should be possible with a good laser. Due to their distinct advantages over gantry (flying head) laser marking systems, including accuracy, speed, and repeatability, as well as their ease of integration into production lines, we only manufacture galvanometer-based (flying mirror) laser systems.

Laser technologies

Since its introduction more than 25 years ago, the Nd:YAG laser has been the industry’s workhorse. Lamp pumps were originally used, but have since been largely replaced by diode pumps. Systems based on diodes are robust and have excellent mean time before failure (MTBF). Some manufacturers claim that diodes can last up to 35,000 hours before failure. As a result of the beam quality of Nd:YAG lasers, the spot size is smaller, which is an advantage. Because of its small spot size and short pulse length, this laser produces a high peak power, making it ideal for engraving deep and leaving crisp, clear marks.

There are three wavelengths available for the vanadate laser: 1064 nm, 532 nm (green), and 355 nm (blue). Similarly, vanadate lasers are diode-pumped and exhibit pulse-to-pulse stability, making them well suited for ablation marking and heat-affected zone (HAZ) applications. Vanadate lasers are used for day/night marking, which involves removing the top coating to allow light to backlight buttons at night – usually by abrading the top coating to reveal a lower surface without damaging it.

The fiber laser was introduced into the world of marking six years ago, and it has been the topic of discussion in virtually every marking opportunity since then. With a fiber laser, the peak power is less than with an Nd:YAG or vanadate laser. Fiber lasers can anneal stainless steel due to their long pulse width and larger spot size, which heats the stainless steel enough to draw out carbon. Currently, only a few fiber-laser manufacturers provide laser sources to third parties for integration into marking systems.